QuantaSperse NBB is a nanotechnology-derived foam knock-down additive (Antifoam) for industrial applications. In industrial processes, foams pose serious problems. They prevent the efficient filling of containers and reduce processes efficiencies/recoveries. De-foaming agents such as QuantaSperse NBB are used to reduce or hinder the formation of foam in industrial processes. QuantaSperse NBB is a water dispersible (ultrafine) innovative antifoam additive used…

QUANTEX ACT OIL is an anti-dusting additive designed to easily coat phosphate and sulphate-based granular fertilisers to provide free flowing dust free granules. The product is formulated with clean oils and special additives that meet the requirements of no polycyclic aromatic hydrocarbons (PAHs) and heavy metals as required by act 36 of 1947. QUANTEX ACT OIL is environmentally friendly with…

Nanotechnology is a fast-growing field in research and industry with more applications discovered daily in the fourth industrial revolution (4IR). It presents an opportunity to solve complex problems such as those associated with the water-energy-food nexus. SabiNano’s R&I division focuses on developing innovative carbon nanomaterial-based technologies for energy, environmental and other applications including advanced nano-enhanced materials for various applications including building and construction, polymers, separation/filtration, adsorption, energy-storage, coatings, automotive/transport industries, electronics, etc.

Our Quantex PBT is a high-performance stabilised liquid antidust (binder) co-polymer of natural esters, acrylamides, long chain carboxylic groups and wetting agents, prepared using nonchemical technology. The functionality of the water-soluble co-copolymer is carefully formulated to enhance the binding onto surfaces, dust/powders and dry to give an excellent long lasting adhesive property.

We supply the most environmentally friendly, profit-friendly technology for water/wastewater treatment and other industrial applications. If you are a small or large company/organization that purifies drinking or wastewater, or a mining company that is unable to purify it wastewater to acceptable standards, then you need to contact us. Our technology is the ideal choice because of its high efficiency and economic value. It is biodegradable, simple to apply, and has flexible properties. We have local and international partners that have vast experience in water treatment technology and compliance to international

standards.

Besides carbon nanotubes and graphene, we supply a wide range of nanoparticles for research and commercial projects. These include nanocellulose, single metal oxide nanoparticles, magnetic nanoparticles, element and alloy nanoparticles, multielement oxide nanoparticles, rare earth materials etc. A complete list can be found on our e-commerce website (www.sabinano.co.za)

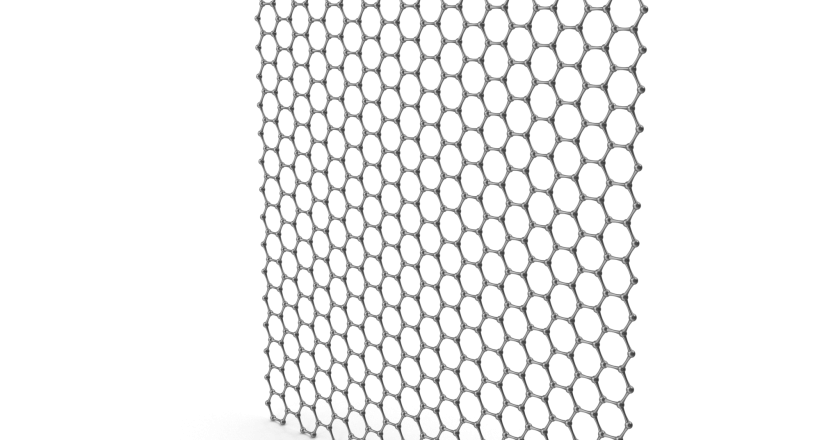

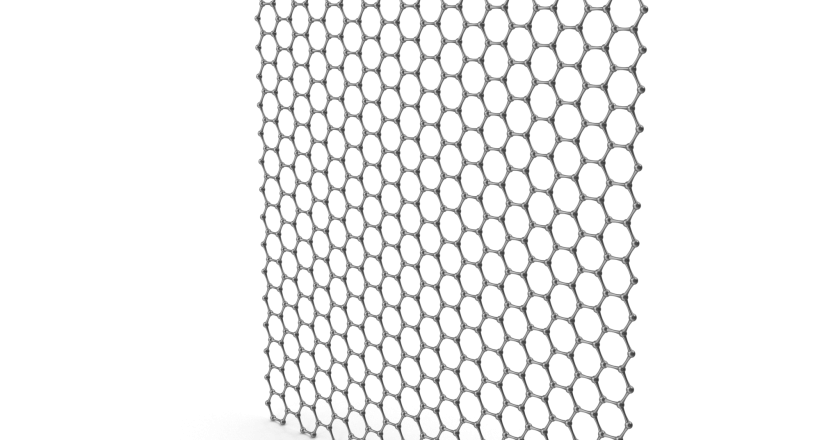

SabiNano has a dedicated inhouse team and strategic partners for design, R&D and production of nano materials with advanced material technologies and conducting studies on new generation products. These products are, but not limited to, carbon nanotubes and graphene for academic research and commercial projects. Graphene and graphene oxide have a wide range of applications across many industrial sectors including modern 4th industrial revolution (4IR) technologies. We have partnered with one of the largest graphene mass production facilities in the world, with an annual graphene production capacity of 100 tons. Our goal is to reach this production scale in SA to enable many of the 4IR in which graphene finds its applications. Our high-quality graphene products are already applied in anticorrosion and light-weight composite materials.

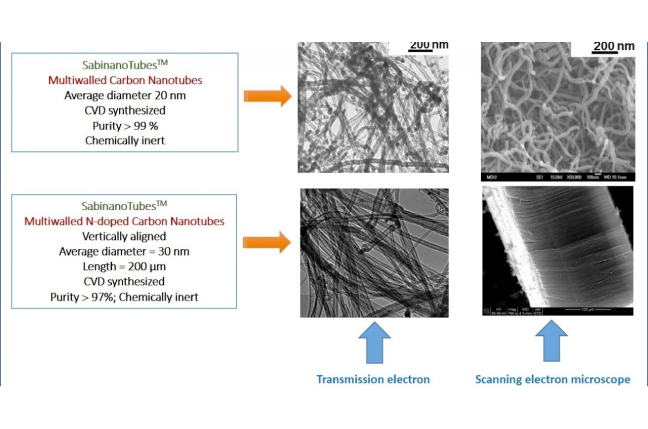

SabiNano manufactures and supplies high-quality carbon nanotubes (CNTs) on a commercial scale. Our multiwalled carbon nanotubes (SabinanoTubesTM) have purities ranging between 90% (industrial grade) and >98% (research-grade) depending on customer needs and the end-use of the materials. Our unique CNT production process entails using a novel, environmentally friendly and economically viable process in a specially designed reactor. We supply in various quantities from grams to kilograms